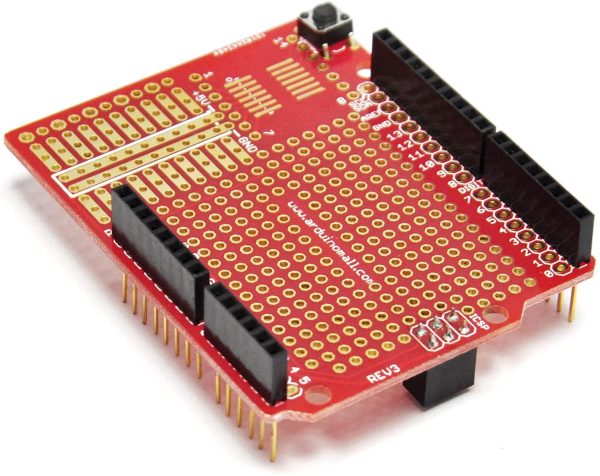

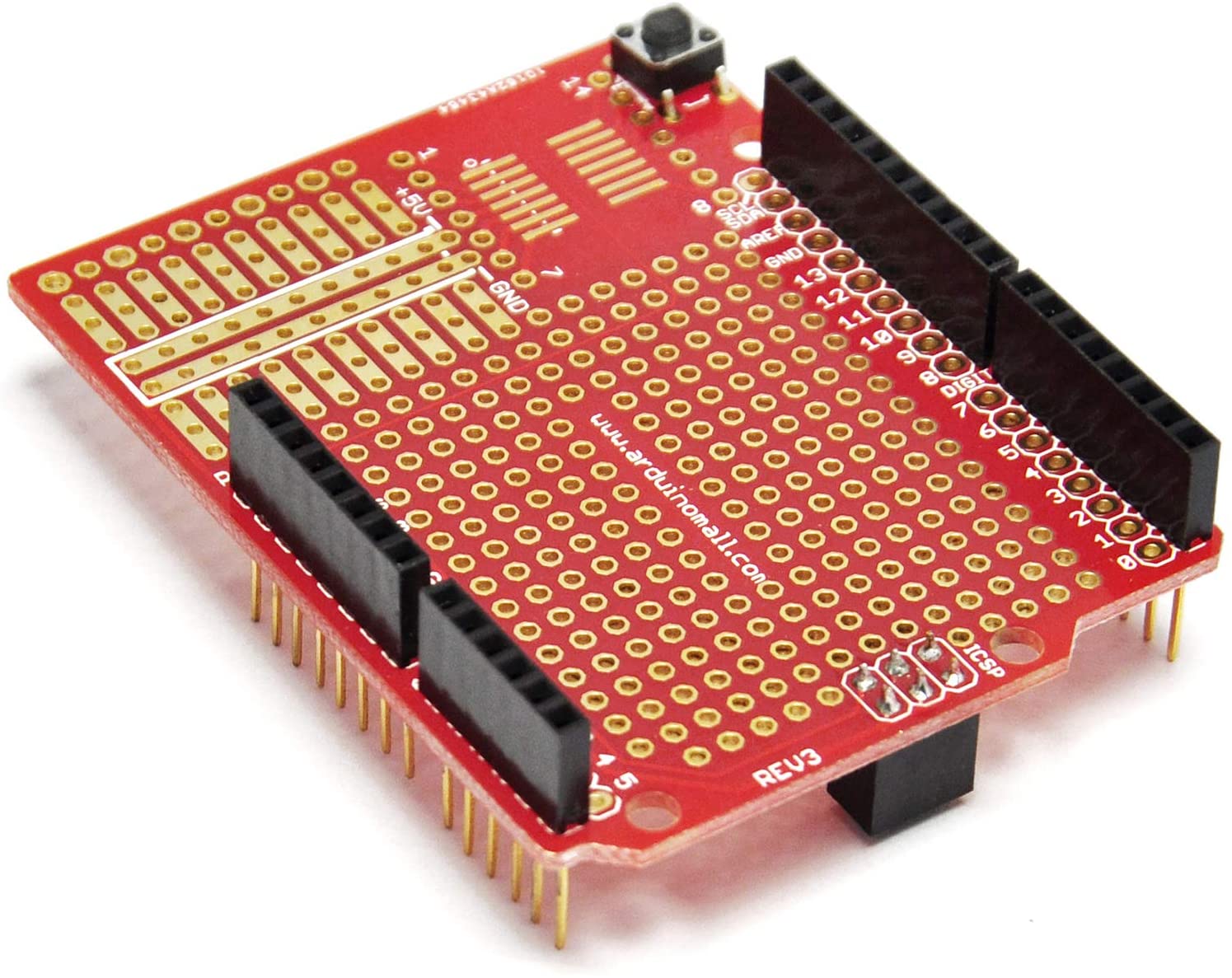

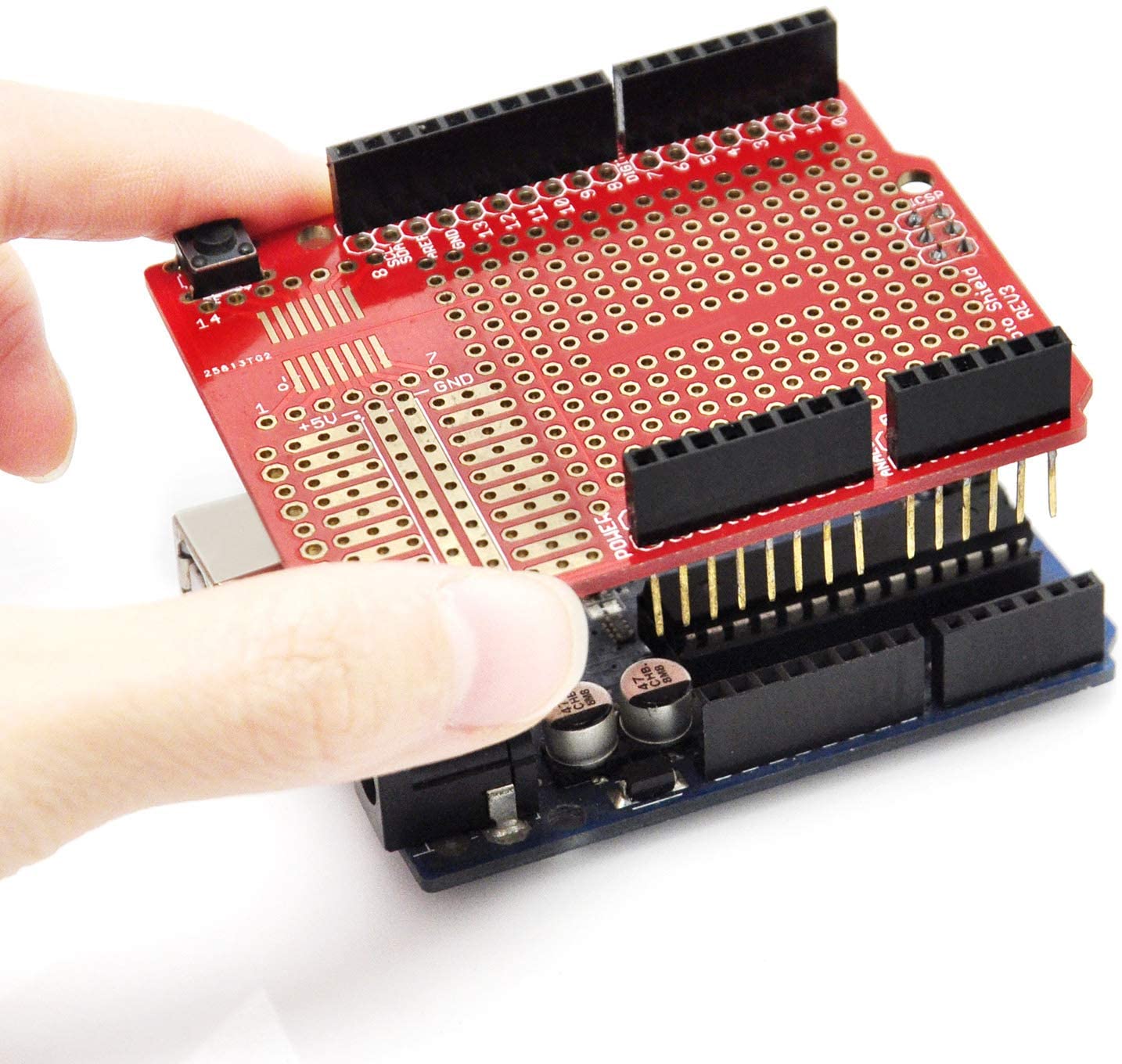

- Large Prototyping Area: Extensive 0.1″ (2.54mm) pitch grid space for soldering custom through-hole components and DIP ICs.

- Integrated Power Rails: Conveniently located 5V and GND power buses simplify circuit wiring.

- On-board LED: Pre-connected LED on Digital Pin 13 for debugging and status indication.

- Easy Access Reset: A dedicated reset button for convenience.

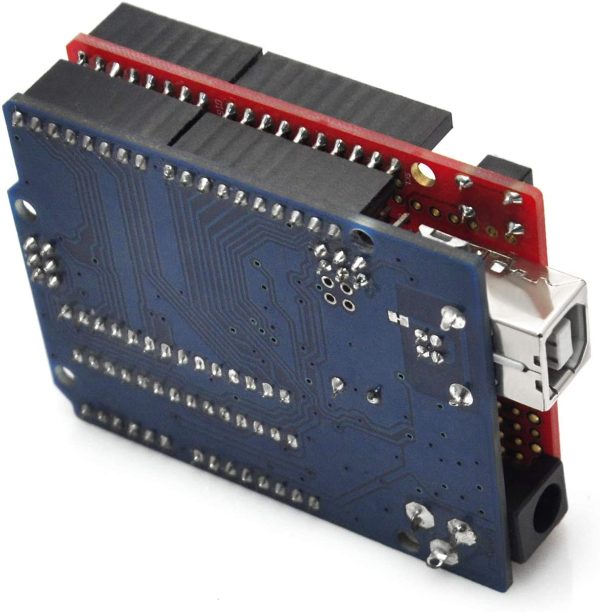

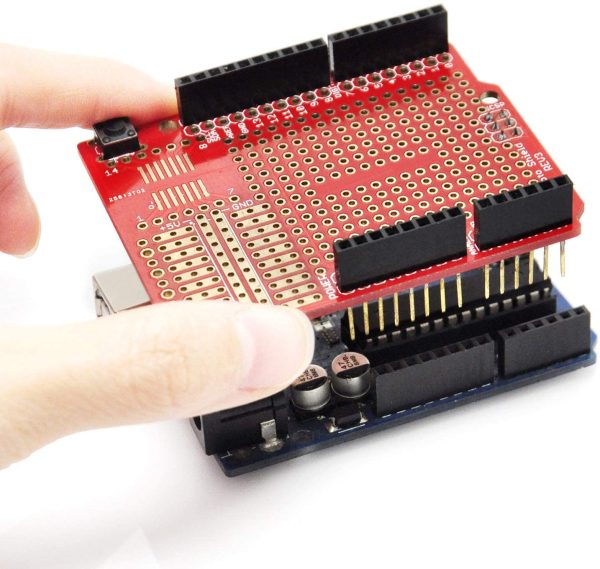

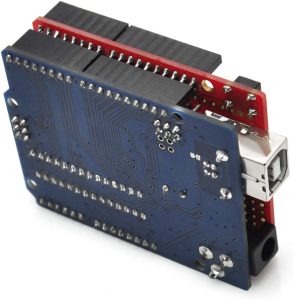

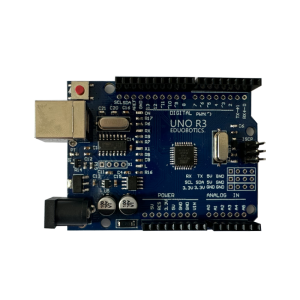

- High Compatibility: Designed for perfect pin alignment with Arduino UNO R3 and Mega 328P microcontrollers.

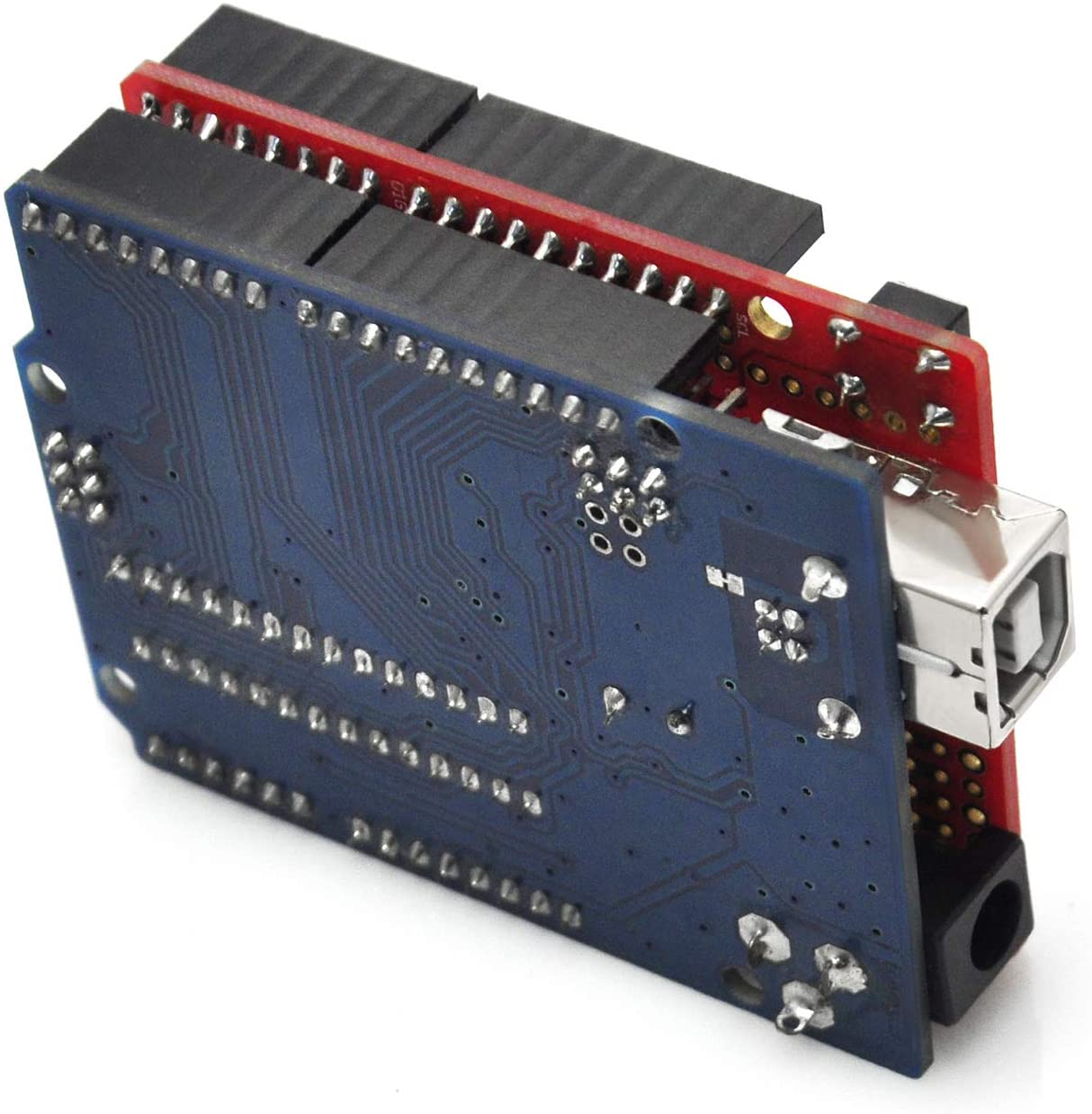

- Durable Construction: High-quality FR4 PCB material ensures longevity and reliable soldering.

- Flexible Design: Plated-through holes allow for easy connection and modification.

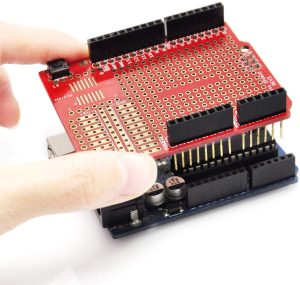

Prototype Shield is suitable for Arduino UNO R3 Mega 328P

| Product Name | Prototype Shield |

|---|---|

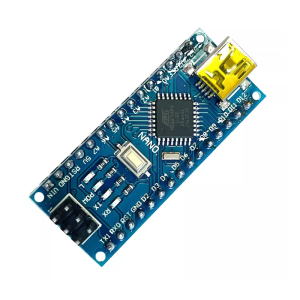

| Compatibility | Arduino UNO R3, Mega 328P boards (and other similar form factors) |

| Prototyping Grid Pitch | 0.1" (2.54mm) standard through-hole spacing |

| PCB Type | Double-sided, plated-through holes |

| Dimensions (L x W) | Approx. 68mm x 53mm (2.7" x 2.1") |

| Included Components | Bare PCB shield only (headers and other components usually sold separately) |

| Operating Temperature | Standard industrial range (e.g., -40°C to +85°C) |

- Finalizing Prototypes: Once a circuit works on a breadboard, this shield is used to solder the components permanently onto a single, robust PCB.

- Custom Hardware Integration: Used by businesses to embed custom circuitry (e.g., specific motor drivers, specialized sensor interfaces) into an integrated, compact form factor.

- Educational Tools: Excellent for teaching permanent circuit assembly and soldering techniques in a structured environment.

- Compact Builds: Enables the creation of self-contained projects without messy wiring or external perfboards.

No, this is typically sold as a bare board. You will need to purchase and solder stacking headers separately to connect it to your Arduino board. This allows you the flexibility to choose between standard headers or extra-long stacking headers.

This “Prototype Shield” focuses purely on providing a large area for soldering components using traditional through-hole methods. The “Proto Screw Shield” primarily offers screw terminals for easy wire connection and usually has a smaller prototyping area.

While primarily designed for through-hole components, some versions have small dedicated areas for common SMD footprints (like SOIC). You can solder SMDs if you are comfortable with the technique, but through-hole is the intended primary use.

Soldering on a prototype shield is a standard electronics skill. The holes are plated-through, making the process straightforward for anyone with basic soldering experience and tools.

No, the design ensures that all original Arduino I/O pins are still accessible at the edges of the shield, allowing you to use those connections or stack another shield on top (provided you use stacking headers).