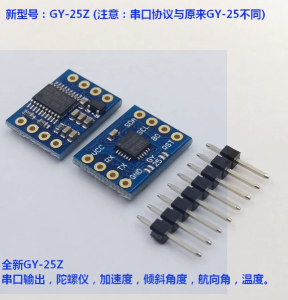

- Industrial Reliability: Built for robust performance in demanding operating conditions.

- Pre-processed Angle Data: Outputs stable Pitch and Roll angles in degrees, requiring minimal host controller processing.

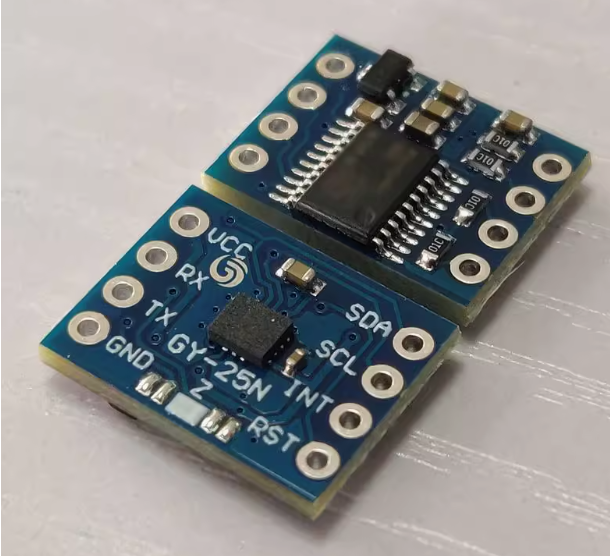

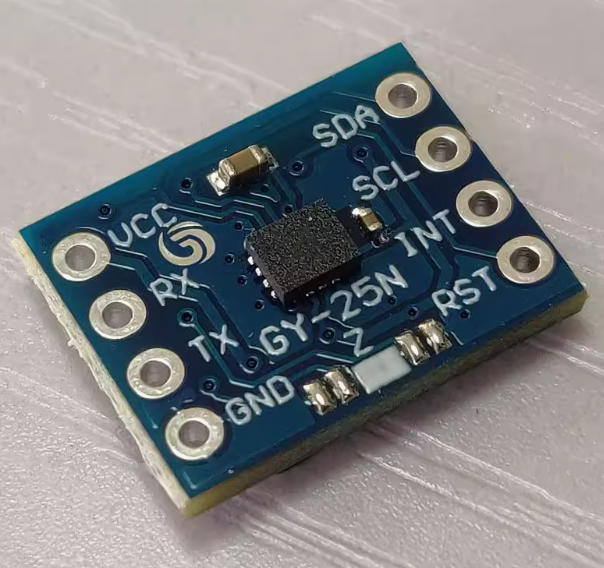

- Dual Communication Interfaces: Supports both UART (Serial TTL) and I2C protocols for versatile integration.

- Integrated 6-Axis Sensing: Combines a 3-axis accelerometer and a 3-axis gyroscope.

- Internal Sensor Fusion: Utilizes DMP technology to minimize drift and stabilize readings automatically.

- Wide Voltage Compatibility: Onboard regulator supports operation from 3V to 5V DC power supplies.

- High Precision: Offers fine resolution typically down to 0.01 degrees

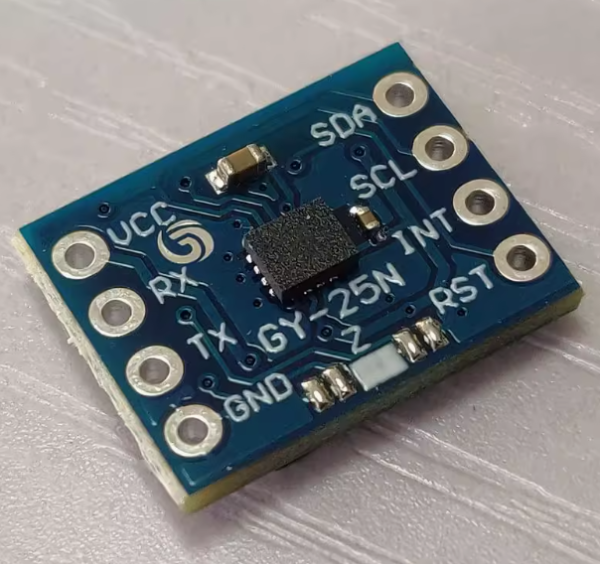

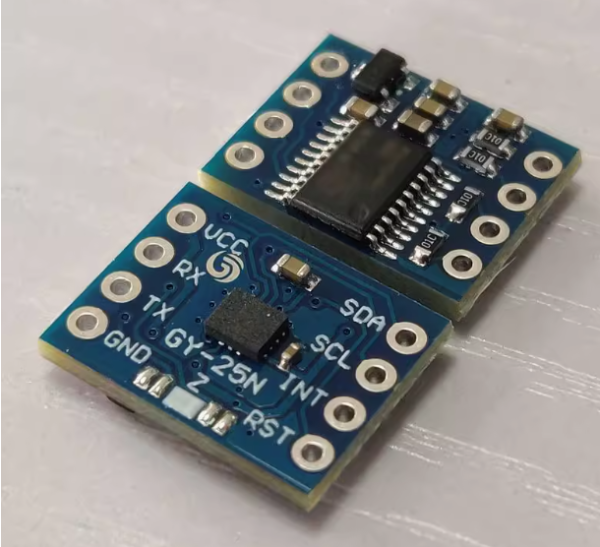

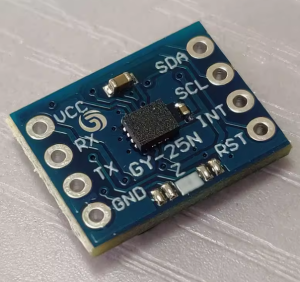

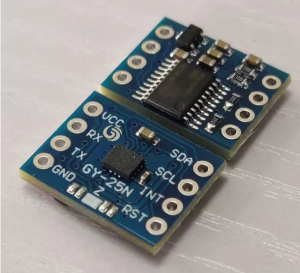

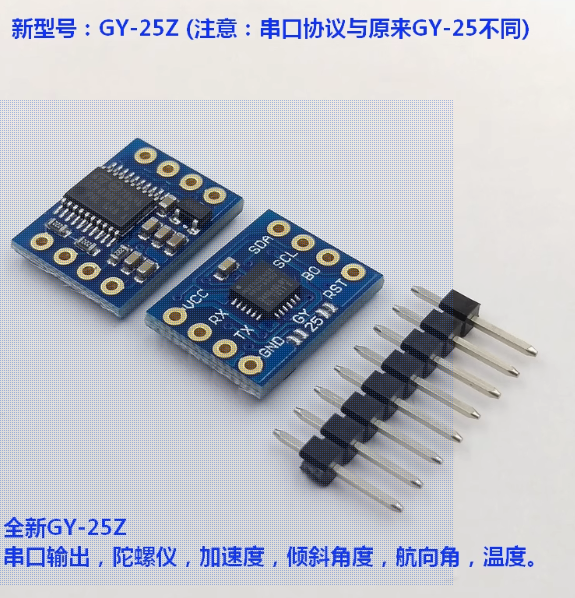

Industrial-Grade GY-25Z Inclinometer – MPU6050 6-Axis Motion Tracking Sensor (UART/I2C Output)

| Sensor Core | Integrated 6-Axis Motion Processor (MPU6050 compatible) |

|---|---|

| Output Data | Pitch Angle, Roll Angle |

| Output Format | Serial (UART TTL) & I2C |

| Supply Voltage | 3.0V – 5.0V DC |

| Resolution | Approx. 0.01° |

| Data Update Rate | Up to 100 Hz |

| Baud Rate Options (UART) | 9600 bps (default) / 115200 bps (configurable) |

| Module Dimensions | Approx. 24mm x 15mm |

- Platform Leveling: Automated leveling systems for scissor lifts, cranes, or satellite dishes.

- Industrial Robotics: Precise angle feedback for robotic arms and automated guided vehicles (AGVs).

- Structural Monitoring: Measuring tilt and vibration in infrastructure or machinery.

- Heavy Machinery Control: Ensuring safe operating angles for construction equipment.

- Connect VCC (3-5V) and GND to your power supply.

- Select the required communication protocol (UART or I2C) via module configuration (check datasheet for specifics).

- Connect the appropriate data pins to your industrial controller or PC interface.

- Read the digitally formatted angle data packets via the chosen interface

This version is typically built with more durable components (e.g., specific capacitors, wider temperature range ICs) and focuses purely on outputting stable, pre-processed angle data with minimal drift, which is necessary for reliable business/industrial use.

No, this module’s firmware is designed only to output the calculated Pitch and Roll angles. For raw data access, use a standard MPU-6050 breakout board.

The primary function of the onboard processor is to run sensor fusion algorithms that actively correct for gyroscope drift using gravity references from the accelerometer, providing highly stable output.

No, the module is designed to be compatible with both 3.3V and 5V power and logic levels directly.

It is excellent for measuring stable angles and general motion tracking. The 100 Hz update rate is sufficient for most automation and robotics tasks, but extreme high-frequency vibration analysis might require specialized hardware